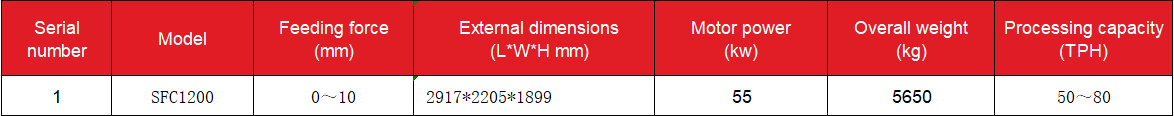

SFC1200 CENTRIFUGE SPECIFICATION

Welcome to inquire and purchase“ SSFC1200 CENTRIFUGE SPECIFICATION”.

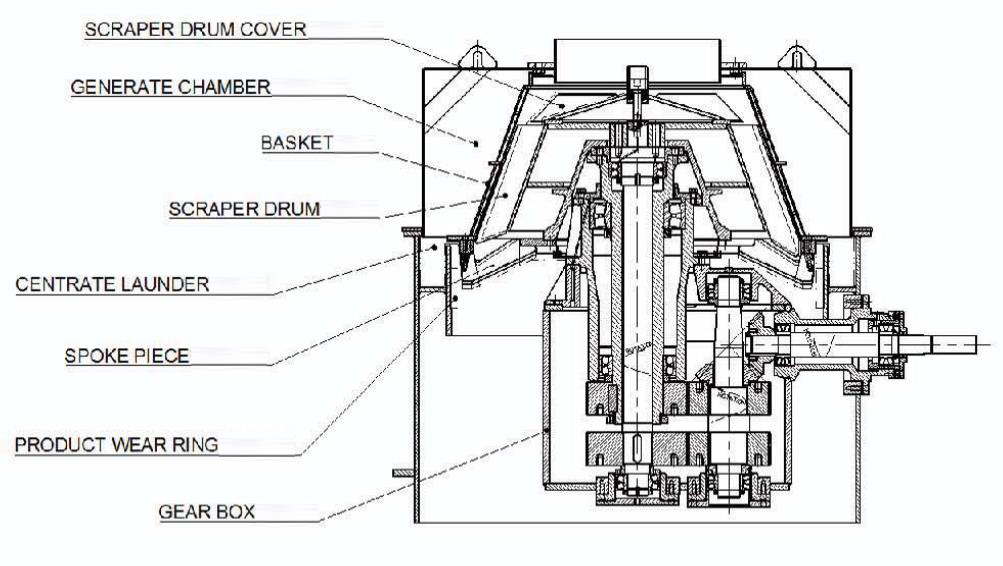

The arrangement of the drive as illustrated here shows the horizontal input drive shaft driving through spiral bevel gears to the helical gear train. The spiral bevel gears drive a vertical intermediate shaft carrying a pair of helical gears, which in turn drive the central main and hollow shafts, which rotate the scraper drum and centrifuge basket respectively. All gears, shafts and bearings are extremely robust and capable of many years of trouble free operation.

1.Supercharged lubrication system for long bearing life.

2.Lubrication failure protection with automatic shutdown.

3.Re-usable oil filter with built in magnet.

4.Blocked filter bypass indicator.

5.Large throat opening for greater throughput.

6.Abrasive resistant wear parts as standard supply.

7.16 conveying fins for greater dewatering.

8.Screen basket liner ensures easy replacement.

9.Heavy duty construction.

10.Performance guarantee.

11.Production warranty.

12.Easy belt change.

Low installation Costs

Minimum Maintenance Costs

High Efficiency

Maximum Solids Recovery

Low Final Moisture

Professional Back-Up & Site Service Support

(a) Internal Base of Spoke Piece lined with 12mm thick Alumina Ceramic Tiles.

(b) Product Wear Ring lined internally with 170mm high x 12mm thick Alumina Ceramic Tiles.

(c) Centrate Chamber High Density Alumina Wear Tiles.

(d) Centrate Launder Trowellable Ceramic Wear Compound (Wear Resist).

(e) Scroll Abrasive Resistant Scraper Blades.

(f) Chute/Distribution Zone